Sustainability and environment

The sustainable action is an integral part of our corporate philosophy. As a manufacturer of stainless steel and FRP water slides with production in Germany, we rely on environmentally conscious processes, durable materials and social responsibility. Our objective: the production of durable products with minimal resource consumption – for a sustainable leisure industry.

Environmentally friendly production

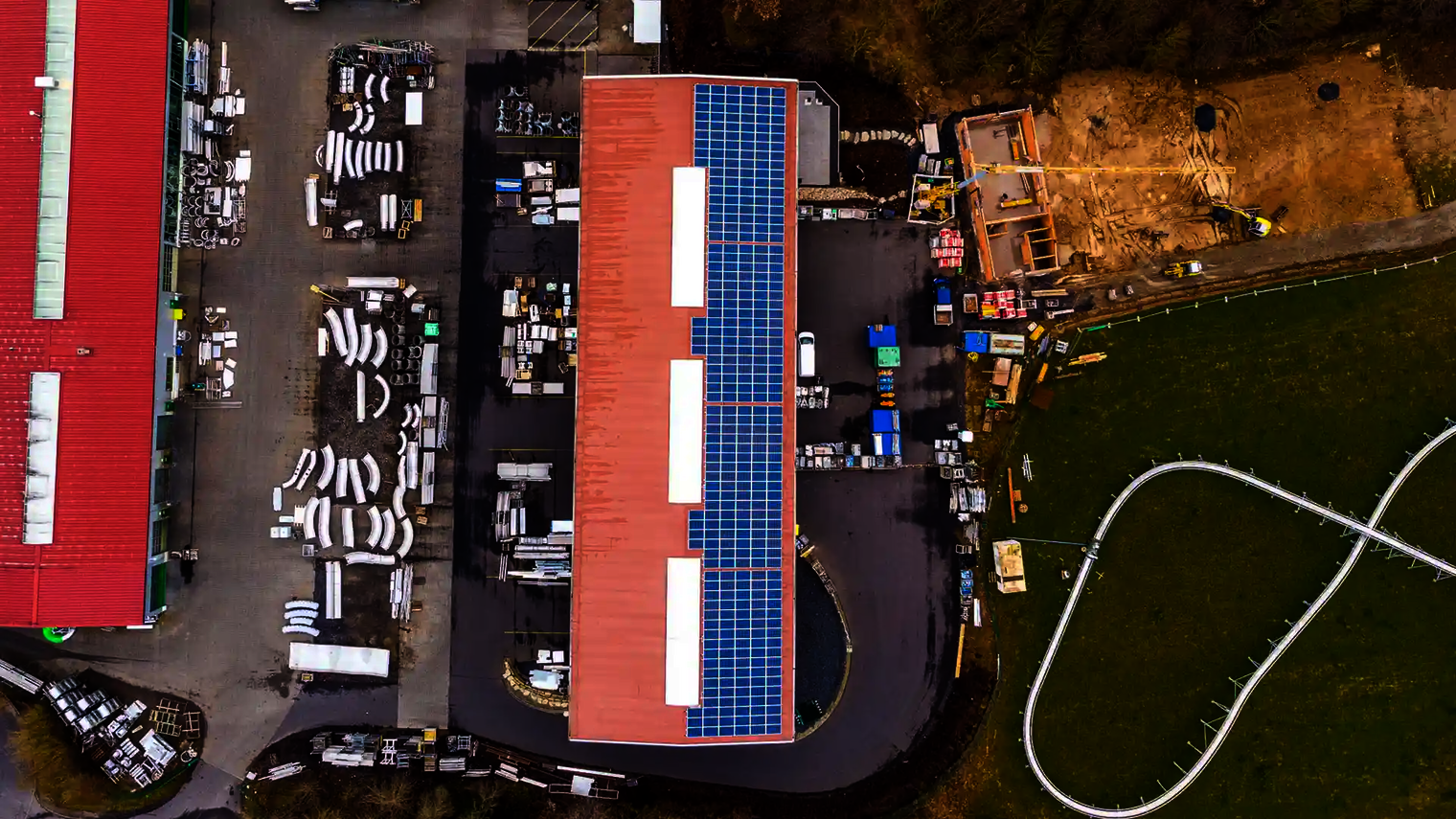

Our Production takes place mostly in Germany – this saves transport routes, reduces emissions and meets the highest environmental standards. We avoid material surpluses through precise planning and construction. During the production process, we pay attention to maximum efficiency and the lowest possible ecological footprint. Modern wastewater and purification systems are used to ensure water quality. Furthermore, we are constantly working on optimizing our processes – for energy self-sufficient production with our own photovoltaic systems securing our power supply at the site.

Resource-saving materials

We are the only manufacturer in the world that, in addition to FRP even produces stainless steel slides in its own factory. Many of our stainless steel slides have been operated for more than 30 years – with minimal maintenance. This saves resources during the entire life cycle. We pursue a production method which is as waste-free as possible, from the receipt of the material to its final assembly. Excess material is deliberately avoided – especially for components without added functional value. Our designs follow a clear principle: form follows function. When planning space, we also make sure that building space and usable space are in a sensible relationship. The balancing act between physical security and resource conservation is the central objective of our development work.

Water and energy saving

Our systems are designed to use as little water as possible. Thanks to optimised sliding surfaces and targeted water supply, the necessary driving effect is achieved with a minimal use of water. In the kids areas, the hand and foot activators ensure that water only flows when it is really required. Our pump systems can also be specifically deactivated via control if no use takes place. This method saves energy during the operation.

Responsibility for employees

More than 30% of our employees have been part of the company for over ten years. This is a clear sign of continuity, trust and long-term prospects. We have a mixed age structure of experienced professionals up to young up-and-coming talents. Through internships and apprenticeships, we enable targeted career entry and knowledge transfer. Our employees benefit from a bicycle subsidy, supplementary occupational health insurance and physiotherapy at the workplace. Occupational safety is our top priority – for this we rely on state-of-the-art welding technology and regular training, especially for our fitters.

Our award: The Brandenburger Umweltsiegel (Ecolabel)

The Brandenburger Umweltsiegel (Ecolabel) honours companies that set up an environmental management system on their own initiative. The award shows that we continue to think about sustainability – with concrete measures, measurable commitment and a clear commitment to environmental as well as climate protection.

Our production plant in Brüssow (Brandenburg) was already awarded the Brandenburger Umweltsiegel (Ecolabel) three times. On this production site, every year around 1.5 kilometres of FRP slides are manufactured. A planned photovoltaic system will supply the site with its own energy in the future. Our international team stands for lived social sustainability through cooperation, responsibility and respect.

We will be happy to advise you on your waterslide project and prepare an individual offer. The maintenance work is also part of our service.