Construction period

The duration of the construction consists of several phases. The first phase is the preparation phase including planning and design, as well as the required as well as the special approvals. This phase may vary depending on the complexity of the project and on the local regulations. It is followed by the production phase, in which the slide body and all components associated with it will be manufactured. The length of this phase depends on the size and on the design of the slide. Finally, the installation takes place on site. This phase can also vary depending on the scope and on the complexity of the installation. Overall, the construction time of a water slide is project-specific and is largely determined by the individual requirements and framework conditions. The specified construction times are non-binding guideline values and could vary individually depending on the project and on the capacity utilization.

CONSTRUCTION STEPS | DESCRIPTION | ESTIMATED DURATION |

Step 1: Preliminary discussion and planning process | ||

| 1. Initial consultation | In this context, we discuss the basic requirements and wishes of the customer by talking out the feasibility of the project. | Between 6 and 20 weeks, depending on the decision-making process |

| 2. Receipt of the construction plans from the customer | The customer provides us with the existing construction plans, on the basis of which we will execute the planning of the slide. | |

| 3. Second meeting with rough draft | We present an initial draft of the waterslide project and discuss the adjustments or modifications. | |

| 4. Price calculation (visualization if necessary) | We calculate the costs of the project and, if it is needed, we also create a visualization of the planned slide. | |

| 5. Creation of the contract | A detailed contract covering all the services and conditions of the project will be drawn up. | |

Step 2: Production process | ||

| A. Technical design | The detailed technical elaboration of the slide, including all specifications and design plans, will be created. | Between 16 and 42 weeks, depending on the production utilization |

| B. Preparation of the production | All necessary steps for the preparation of the production, such as for example material procurement and planning of the production processes, are carried out. | |

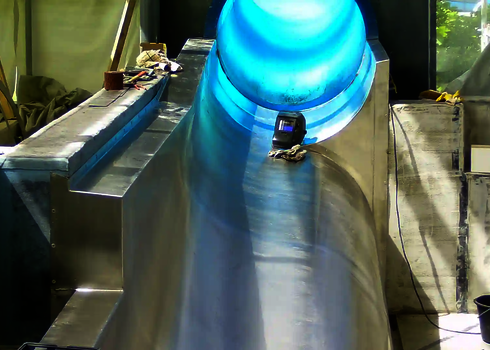

| C. Production | The actual production of the water slide and its components will take place in our own production sites. | |

| D. Delivery | The finished parts of the slide will be transported to the installation site by land, air or sea freight. | |

| E. Assembly | The professional assembly of the water slide at the destination will be carried out by our assembly teams. | |

| F. TÜV acceptance | The finished slide will be inspected by TÜV in order to ensure its compliance with all applicable safety standards. | |

| G. Opening | After the successful completion of all surrounding trades, the water slide can be officially opened. | |

All values are indicative and depend on the capacity utilization, on the national specifications as well as on other factors and/or service providers.

Costs and Purchase

The Costs for a water slide vary depending on the product, location and scope of the provided services. A simple indication of costs is not feasible, as each project is individually evaluated and offered. The construction costs can be broken down into different services in order to enable a detailed cost statement.

The costs depend on several factors, including the following ones:

- Size and length of the slide

- Material (stainless steel or FRP)

- Additional functions (for example: LED Light Effects, Virtual Reality)

- Location and installation effort

For an individual offer we create a tailor-made calculation.

Upon request, when purchasing a water slide, the customer not only receives the slide itself, but also stairs, towers, start and run area as well as potential special effects. The delivery also includes the entire planning documents and, of course, the applicable guarantees. In addition, a TÜV certificate for operational readiness can be issued. Static calculations and technical requirements for water technology are planned by us while the foundations as well as the water technology are usually provided by the customer.

Choosing between FRP and Stainless steel depends on many factors. Although stainless steel can be slightly more expensive to purchase, the follow-up and maintenance costs are much lower, and the service life is longer than that of GRP when properly maintained. On the other hand, FRP moulds can be shaped individually and also offer a higher degree of design freedom in terms of visual presentation. This can be a key success factor. For this reason, it is not clear which material is the best choice.

Stainless steel is almost maintenance-free if it is used and cared about properly. FRP on the other hand, is more susceptible to damage from sunlight and mechanical wear. For this reason, an annual maintenance is mandatory. As a consequence, stainless steel offers advantages in terms of maintenance costs as well as in terms of durability.

Yes, Wiegand water slides are sold worldwide. We are in many countries, from China to Cuba, and have an extensive network to for the global distribution and installation of the slides. From here you can reach our Reference Projects.

If you purchase a water slide, the construction situation on site is the first criterion determining what is feasible. It is important to select the correct product, check the statics and construction options, calculate the production times and construction costs and finally plan the implementation. A careful planning and a consideration of all factors is critical to the success of the project. For this reason, professional advice and concrete planning is recommended.

Our slides are designed to have a long service life and low maintenance costs. Their profitability depends on the number of visitors, water and energy costs as well as maintenance costs.

The payback period depends on the operating costs and on the frequency of visitors. The operators usually expect a payback period of around 5 years.

Yes, in addition to water slides, we also manufacture Dry Slides made of stainless steel, including, for example, escape slides, playground slides, large slides and much more. The areas of application range from amusement parks to shopping centres to office buildings. Go directly to the manufacturer of dry slides: www.wiegandslide.de

We will be happy to advise you on your waterslide project and prepare an individual offer. The maintenance work is also part of our service.