Implementation

With over 350 dedicated employees at our two German production sites in Rasdorf and Brüssow, we are proud to be the leading manufacturer of water slides in the region. Our own production facilities specialise in the processing of high quality steel and glass fibre reinforced plastic (FRP). This enables us to manufacture water slides of unsurpassed quality and durability. Our manufacturing expertise, coupled with innovative technology and creative design, ensures that each of our slides offers a unique experience.

At the heart of our success are our own assembly teams. These teams combine the expertise of our designers with practical experience in order to ensure an efficient and precise installation of our water slides. Thanks to the close cooperation between our planners and installers, we can ensure that each project not only meets the highest quality standards, but is also individually tailored to the requirements of our customers.

Our site in Rasdorf, Germany

Our headquarters in Rasdorf, Germany, is the central control element of wiegand.waterrides. Here the management as well as all the departments for project planning, design and administration are located. The complete production of black and stainless steel components also takes place in Rasdorf. The same applies to the final assembly and worldwide shipping of our high-quality leisure attractions. This means that this location forms the logistical and organisational basis of our global success.

Site in Brüssow, Germany

In our specialised production facility in Brüssow, the focus is entirely on the production of glass fibre-reinforced plastic (FRP). Here an experienced team of specialists realises the complete FRP product range, from the colorful slides for kids to the complex large slides such as the Lotus. The highest production quality and a deep understanding of materials make the site of Brüssow the centre of our FRP expertise.

Would you like a quote?

We are glad to create an individual water slide offer for your project.

Get in touch with us Request a quote

Continue to immerse yourself in our world of water slides.

What is included in the scope of services?

The following services are available in our portfolio:

- Concept and planning

- Production

- Shipment

- Slide assembly including the steel structure

- TÜV acceptance

We serve the complete design, planning, manufacture, delivery and installation of the water slide. In addition, some services are necessary for the preparation of the assembly work.

What is not included in the scope of services?

Please note that we are not an all-in-one provider. In order to permit the setting up of a slide, you must do some preparatory work. In general, the customers usually commission and successfully execute the following components regionally before the installation of the water slide:

- Foundations

- Water Technology

However, we will support you find the suitable provider and present our building requirements.

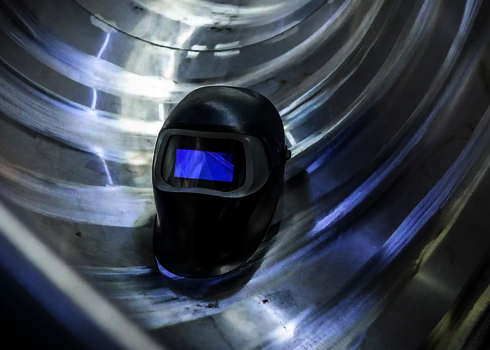

Our assembly team

Our highly-qualified assembly team brings extensive experience in slide assembly. And this experience is reflected in every project. Our trained skilled workers are on the road all over the world in order to carry out demanding slide installations. The focus is on working closely with our design department and project management so to ensure that every assembly is carried out precisely and according to the highest standards. Our team is known not only for its craftsmanship excellence, but also for its ability to flexibly adapt to the individual requirements of each project.

Costs and Purchase

The Costs for a water slide vary depending on the product, location and scope of the provided services. A simple indication of costs is not feasible, as each project is individually evaluated and offered. The construction costs can be broken down into different services in order to enable a detailed cost statement.

The costs depend on several factors, including the following ones:

- Size and length of the slide

- Material (stainless steel or FRP)

- Additional functions (for example: LED Light Effects, Virtual Reality)

- Location and installation effort

For an individual offer we create a tailor-made calculation.

Upon request, when purchasing a water slide, the customer not only receives the slide itself, but also stairs, towers, start and run area as well as potential special effects. The delivery also includes the entire planning documents and, of course, the applicable guarantees. In addition, a TÜV certificate for operational readiness can be issued. Static calculations and technical requirements for water technology are planned by us while the foundations as well as the water technology are usually provided by the customer.

Choosing between FRP and Stainless steel depends on many factors. Although stainless steel can be slightly more expensive to purchase, the follow-up and maintenance costs are much lower, and the service life is longer than that of GRP when properly maintained. On the other hand, FRP moulds can be shaped individually and also offer a higher degree of design freedom in terms of visual presentation. This can be a key success factor. For this reason, it is not clear which material is the best choice.

Stainless steel is almost maintenance-free if it is used and cared about properly. FRP on the other hand, is more susceptible to damage from sunlight and mechanical wear. For this reason, an annual maintenance is mandatory. As a consequence, stainless steel offers advantages in terms of maintenance costs as well as in terms of durability.

Yes, Wiegand water slides are sold worldwide. We are in many countries, from China to Cuba, and have an extensive network to for the global distribution and installation of the slides. From here you can reach our Reference Projects.

If you purchase a water slide, the construction situation on site is the first criterion determining what is feasible. It is important to select the correct product, check the statics and construction options, calculate the production times and construction costs and finally plan the implementation. A careful planning and a consideration of all factors is critical to the success of the project. For this reason, professional advice and concrete planning is recommended.

Our slides are designed to have a long service life and low maintenance costs. Their profitability depends on the number of visitors, water and energy costs as well as maintenance costs.

The payback period depends on the operating costs and on the frequency of visitors. The operators usually expect a payback period of around 5 years.

Yes, in addition to water slides, we also manufacture Dry Slides made of stainless steel, including, for example, escape slides, playground slides, large slides and much more. The areas of application range from amusement parks to shopping centres to office buildings. Go directly to the manufacturer of dry slides: www.wiegandslide.de

We will be happy to advise you on your waterslide project and prepare an individual offer. The maintenance work is also part of our service.