Maintenance

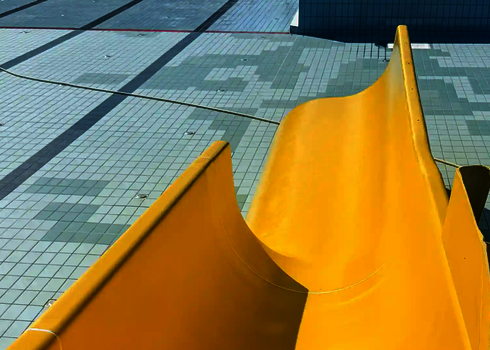

The long-term operation of water slides requires continuous care and maintenance in order to ensure safety and functionality at the highest level. At the company wiegand.waterrides we offer comprehensive maintenance and services including both our own and third-party products.

Our specialist technicians ensure that your systems meet the highest safety standards and operate in a smooth way. From regular inspections to repairs and replacement of worn components, our service covers all main sectors. Thanks to our experience of many years, we know what is essential when it comes to the care of stainless steel and FRP slides. In this context, we attach great importance to identifying potential deficiencies at an early stage and to resolving them in a targeted manner. This not only saves costs due to downtime, but also ensures the long-term attractiveness of your slides.

Maintenance

The regular maintenance is crucial in order to ensure the longevity and safety of water slides. At the company wiegand.waterrides we offer a comprehensive maintenance service tailored to the specific requirements of different slide systems.

Many operators are faced with the challenge of whether a partial or full renovation of their water slide makes sense. While a partial renovation specifically repairs or replaces damaged or heavily stressed segments, a full renovation covers the entire system.

| Partial refurbishment | Full refurbishment | |

| Advantages |

|

|

| Disadvantages |

|

|

Scope of maintenance

-

Inspection and testing:Check all relevant components such as for example screw connections, joints and surfaces for damage and wear.

-

Repair works:Removal of sharp edges, rust spots and other safety-related defects.

-

Material care:Depending on the slide material (stainless steel or GRP), specific measures such as grinding, welding or pickling will be carried out.

-

Maintenance period: The most sensible is to carry out maintenance work out of season or during scheduled closing times so as not to impair bathing operations.

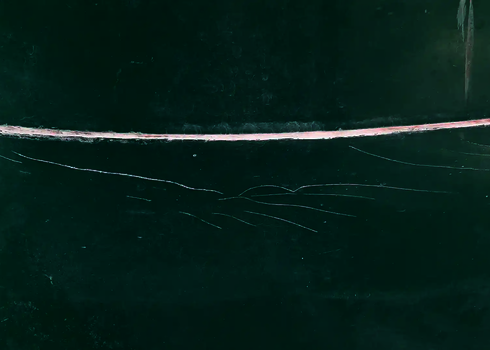

A frequent maintenance measure is the repair of soft joints between the slide elements. The said joints are subject to natural wear and must be replaced at regular intervals in order to avoid any leaks and unevenness. As an alternative, you can use hard joints. They are more durable and require less maintenance. However, they require a higher installation effort.

What grouting is recommended for a renovation?

| Hard grouting |

|

| Soft grouting |

|

Whether a partial or full renovation makes sense depends on the condition of the slide, the age and the intensity of use. In many cases, thorough maintenance with targeted partial renovations can extend the service life. However, in the case of highly obsolete systems, a full renovation is recommended in order to ensure long-term operation.

Maintenance request

Repair GRP and stainless steel

Even high-quality water slides are subject to natural wear and tear due to intensive use and weather conditions. In order to ensure operational safety, we offer a comprehensive repair service for stainless steel and GRP chutes, both for our own products and for third-party products.

Stainless steel repair options

- Elimination of dents and deformations

- Replacement of damaged Makrolon discs

- Removal of rust and stabilization of affected supports

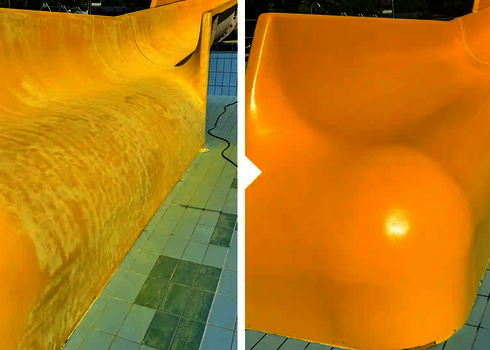

Repair options for GRP

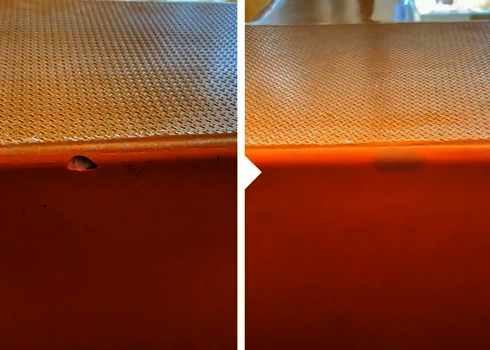

- Repair of cracks and chipping

- Color refresh for faded areas

- Repair of worn sliding surfaces

- Repair of joints (soft and hard grouting)

- Sealing of damaged areas

- Surface repair (topcoat, gelcoat and resin work)

Repair options for the other elements

- Replacement of overflow grille and gratings

- Preparation of stair steps and railings

- Replacement of information signs

Mechanical damage, for example from swimwear with metal parts or weather conditions such as frost, often leads to cracks in the GRP. In these cases, the material is purposefully sanded down and repaired with new GRP mats in order to restore its stability and slipability.

Replacement of an element

If a water slide is irreparably damaged by heavy wear or external influences, we offer a professional replacement of single elements of the water slide. This replacement applies to both GRP and stainless steel components.

Sequence of element replacement

- Damage analysis:Thorough examination of the damaged sections

- Diassembly:Safe removal of the defective element (for example: GRP, Makrolon or acrylic)

- Installation:Installation of the precisely fitting spare part

An acrylic slide element which has become brittle due to strong sunlight can be replaced by a new element.

Cleaning

The regular cleaning of water slides is essential in order to maintain their attractiveness and functionality. At the company wiegand.waterrides, we offer specialized cleaning services including both GRP and stainless steel slides.

Cleaning of GRP slides

- Surface cleaning with specially developed cleaning agents

- Elimination of limescale and algae deposits

Cleaning of stainless steel slides

- Grinding and pickling for rust removal

- Surface polish for long-lasting protection

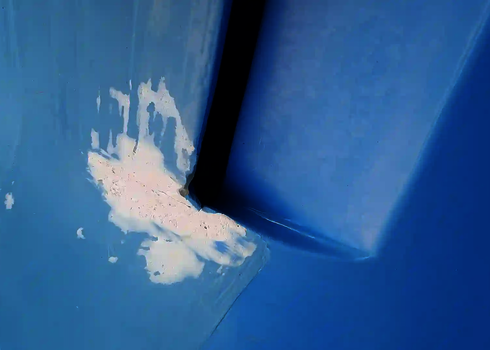

The limescale deposits on GRP slides are often caused by hard water. The affected areas are treated with a special cleansing gel so that the sliding surface becomes flawless again.

Training offer:Upon request, we can also train your team to carry out regular cleaning work independently.

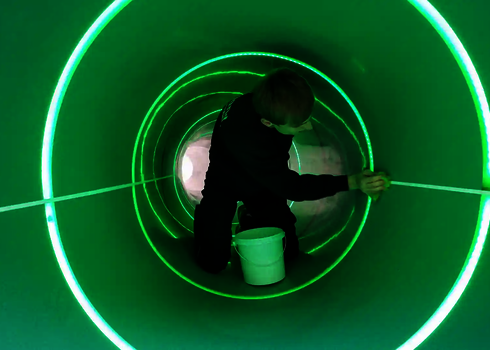

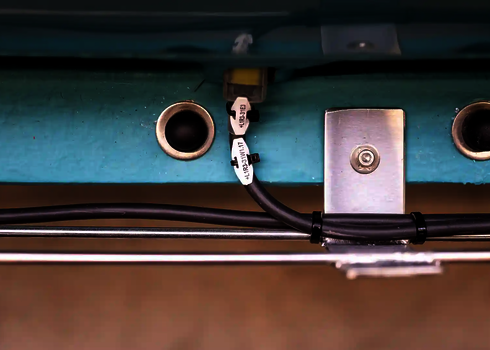

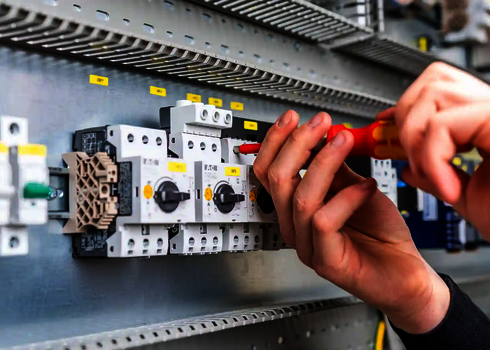

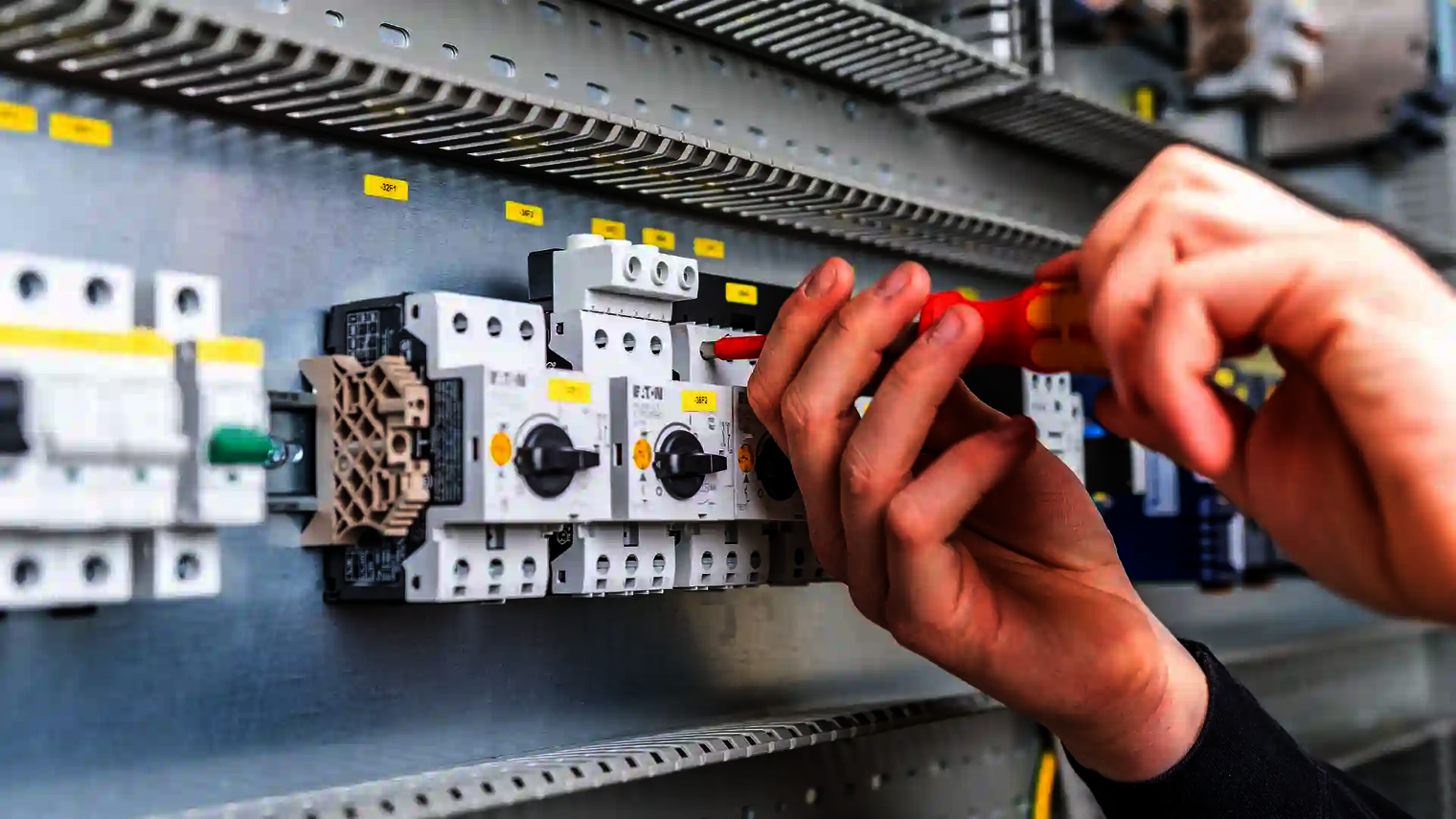

Service Electronics

Modern water slides are often equipped with electronic controls and lighting effects. In order to ensure the functionality of these systems, we offer targeted maintenance and repair work.

Scope of services

- Replacement of defective components: time and sensor lights, control components

- Retrofitting of LED technology: improvement of the visual attractiveness

- Remote maintenance: for compatible systems for quick problem detection

A common service case is the failure of LED lighting effects caused by the penetration of water into the control box. At this point, the careful drying and resealing takes place. This operation is then followed by the replacement of the affected modules.

Service and maintenance

Our FRP water slides require regular Maintenance according to the standard DIN EN 1069. Our service team carries out annual inspections, repairs, cleanings and upgrades to increase safety, performs professional cleaning and repairs slides regardless of the manufacturer. We will be glad to draw up a maintenance contract with you. Request service now.

The operation of a water slide requires compliance with the DIN EN 1069 standard as well as regular safety tests. The operators must carry out maintenance, ensure water quality and check the slide system for damage. Emergency procedures and clear safety instructions for guests are also required.

The water quality has a direct influence on the longevity as well as on the preservation of the slide materials. Too high chlorine or salt contents can accelerate the corrosion in metal parts such as Stainless steel and can attack surfaces of FRP slides. For this reason, careful monitoring and regulation of water chemistry as well as regular maintenance are essential to minimise material wear and to extend the life of the slide.

The regular Cleaning of FRP (glass fibre reinforced plastic) slides is essential for their durability and safety. Our Service - Team offers professional cleaning services for your slides, both indoors and outdoors. Damaged areas are polished and the slides are thoroughly cleaned, especially before commissioning at the beginning of the season. For optimal care, we recommend carrying out these cleaning measures on a regular basis.

The regular Cleaning of stainless steel slides is essential for their durability and safety. Our Service - Team offers professional cleaning services that include both polishing damaged areas and thorough cleaning of the indoor and outdoor slides. Especially before the start of the season, careful preparation of the slides is important to ensure optimal sliding conditions.

The steel elements of a slide should be regularly cleaned and maintained in order to prevent corrosion and build-up. Our Service - Team offers professional cleaning services, including polishing and protective measures for the long-term preservation of the surfaces. Especially before the start of the season, thorough cleaning is advisable in order to keep the slide in optimal condition.

In order to ensure that the water slides are used for a long time, regular Maintenance and care of the individual components must be guaranteed. A maintenance joint is replaced as follows:

During the first step, the old existing seal must be cut out of the joint without residue by using a sharp cutter knife. After that, the edges must be carefully ground in order to ensure the adhesion of the new seal. During the next step, the area must be thoroughly cleaned and taped. Now the new joint can be filled with new sealant.

The damage to water slides can usually be professionally repaired. Our service team takes care of repair work on both our own slides and on systems from other manufacturers. We repair damage to sliding surfaces, landing pools, stairways and joints. Furthermore, we take care of the renewal of ageing acrylic or macrolone elements. Our qualified fitters ensure that your slide is safe and functional again as soon as possible. Request Service now.

Yes, we offer various warranties for our products. This warranty covers various situations and is contractually stipulated. Wear parts are not subject to any warranty.

We will be happy to advise you on your waterslide project and prepare an individual offer. The maintenance work is also part of our service.